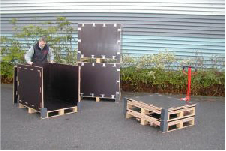

Export Crates

Choosing the right export crates is vital in ensuring that your valuable products will arrive at their international destination in perfect condition and for the lowest possible cost to your business.The Crocodile export crate is a top-of-the-line solution for shipping and exporting goods safely and efficiently. Our wooden export crates are constructed with rebated timber sheets such as plywood, OSB, chipboard or a combination of these, and secured with our unique clip system. These export crates are available in flat-pack form to save on transport costs. The assembly process is fast, safe and requires no tools. The Crocodile export crate comes with an integral pallet base and internal surfaces that are free of battening, allowing for easy customisation to hold and protect your products. Our ultimate goal is to provide 100% protection against damage to your products during transit. We take great care in securing the items, protecting against in-transit vibration and moisture damage, and simplifying the loading and unloading process.

What makes the Crocodile Export Shipping Crate the best solution?

Rebated panels.

- Seamless fit

- The Crocodile rebated design means that wood is always pushing against wood – as long as the panels are aligned it is almost impossible for the crate to collapse.

- We machine our panels to close tolerances so that the rebates fit snugly and provide high levels of strength.

- The tight tolerances provide effective weather-proofing. Water will have to find its’ way around the plywood rebates before entering the wooden export crates and, as it does, the dampness will cause slight temporary swelling which will bring additional sealing to the join.

Market leading strength.

- Pure Strength

- The super-strong Crocodile wooden export crates can withstand over 15,000kg of compression bearing on the bottom crate.

- The stronger the wooden export crate, the higher the protection levels which is why our aim is always zero damage to the product being shipped.

- Rough handling at some point during an export journey is almost inevitable but the Crocodile system ensures a high chance of limiting damage to the shipping crate which allows re-use and ultimately will cut costs within your supply chain.

Customised internal protection.

- 3D protection

- Your product is probably unique – its shape, weight distribution, mounting points and finishes will require a properly thought through protection system to ensure arrival in perfect condition.

- We can help you to develop 3 dimensional foam protection within the export crate support to ensure that impact energy from any direction will be deflected and minimised.

- The internal faces of a Crocodile case are just a smooth wall so it’s easy to design ways to secure your product safely with no movement and protect it from harmful vibration during it’s journey.

Stackable – up to 8 high.

- A self-warehousing system

- Super strong Crocodile export crates can be stacked up to 8 high – the limiting factor will usually be the forklift rather than the Crocodile case.

- Minimising storage areas by stacking high can save time and considerable costs when off-loaded or trans shipped at a distribution hub – this may happen more than once during a long international journey so the cost savings can add up.

- Expensive racking may not be needed for temporary storage of Crocodile export crates – if you are stacking up like-for -like footprint size crates then good organization labelling can mean that racking systems are not needed.

Collapsible clip system.

- The disappearing crate

- Once the product has been removed the export crate is only protecting a volume of fresh air! Collapsing and flat-packing the crates will take up a fraction of the space of a fully assembled crate. Crocodile export crates can be collapsed with no special tools and with no damage to the panels or clip slots.

- Usually a standard Crocodile crate can be safely collapsed or re-built in about 2 minutes, depending on the size and shape.

- If the crate is not too high it will flat-pack to 20% of it’s original size meaning that storage and transport costs will be just one fifth of a similar non-collapsible crate.

Removable panels.

- Fast flexible panel access

- Any panels can be individually removed from a Crocodile export crate without the need to unpack the whole crate. Simply remove the appropriate clips and ease off whichever panel you choose. To replace the panel simply reverse the operation and snap the clips back into place.

- Leaving off some of the panels can make loading and packing operations swifter and also safer, because manual handing into an open sided case is so much easier.

- Removing a lid or side panel is also ideal for quality control inspections. Likewise, adding specific despatch paperwork post-packing and facilitating customs inspections to fast-track your product to its destination.